Quality Control Inspection

We have applied Quality Control Inspection into every work process in our company.

The inspection starts from receiving raw materials from our credible suppliers. Every incoming raw material must be submitted with the certificate of chemical composition analysis. After being examined and permitted by Quality Control Department, subjects will be transferred into the storage.

Chemical Composition analysis of castings is always tested during melting whether it is following the standard according to customer’s demand.

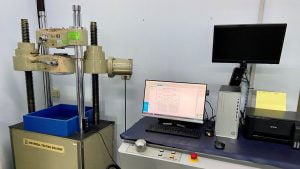

After casting, Mechanical Properties of product are examined by using a sample in casting process for Impact, Tensile, and Hardness testing. To create the testing sample, molten metal from the process is poured into a standard mould. Afterwards, it is tested to identify the impact, tensile, or hardness properties.

Lastly, Non-Destructive Testing and Physical Measurement on final products after machined in our facility are the final two inspections before delivery to clients.

1. In-Process Control

2. Destructive Properties Testing

3. Non-Destructive Testing (NDT)

4. Microstructure Testing

For the Internal Research and Additional Requests from Customers.