Machining & Heat Treatment Department

| Machining Shop’s Overview | |

|---|---|

| Type of Machining: | – 7 CNC Machining – 9 Manual Machining – 1 Drilling Machine |

| Annual Machining Volume: | 250 pcs. |

| Type of Furnace | – 1 Vacuum Horizontal Load Furnace |

| Applicable Products for Heat Treatment: | – Stainless Steel – Super Duplex |

| Heat Treatment Furnace Usage: | To implement casting product’s microstructure in order to improve its mechanical property and corrosion resistance |

Machining Department

List of Machines in PCS 3

| CNC Machining | Manual Machining |

|---|---|

| 2 CNC Horizontal Boring and Milling Machine | 2 Manual Horizontal Boring and Milling Machine |

| 2 CNC Vertical Lathe | 2 Manual Vertical Lathe |

| 1 CNC Lathe | 3 Manual Lathe |

| 2 Vertical Machining Center | 2 Milling |

| Drilling | |

|---|---|

| 1 Hydraulic Clamping Radial Drilling Machine |

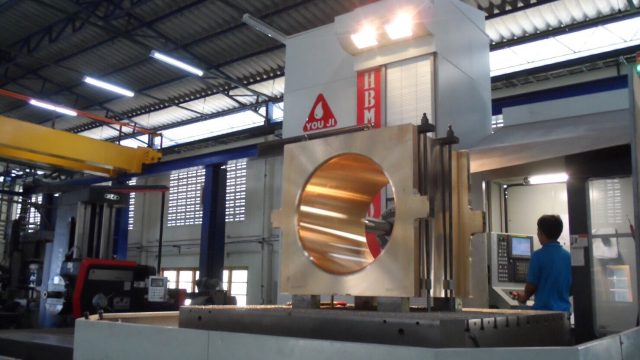

CNC Horizontal Boring Machine HBM 130

Table Diameter : 1,800 x 1,800 mm

Z Travel : 1,250 mm

W Travel : 750 mm

Spindle Speed : 2,500 rpm

Maximum Weight of Workpiece : 12,000 kg

CNC Vertical Lathe VTL 1600ATC-I

Table Diameter : 1,600 mm

Maximum Height : 1,800 mm

Maximum Weight of Workpiece : 8,000 kg

CNC Machine Center SV1100B

Table Diameter : 1,120 x 560 mm

X Y Z Travel : 1,020 / 600 / 635 mm

Spindle Speed : 6,000 rpm

Maximum Weight of Workpiece : 1,000 kg

Work in Progress

Heat Treatment Department

Vacuum Horizontal Load Furnace

Working Zone Size : 1,200 x 1,200 x 1,200 mm

Maximum Weight : 1,000 kg

Maximum Temperature : 1,250 C°

Maximum Quenching Pressure : 10 Bar of N2